Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RainstormZA's Vape and DIY Diary

- Thread starter RainstormZA

- Start date

The only issue I'm having is soldering wire to the torch switch. I've destroyed 3 already

Any advice?

Any advice?

Is that the TP4056 charger module ?

Yes it is.Is that the TP4056 charger module ?

Anyone?The only issue I'm having is soldering wire to the torch switch. I've destroyed 3 already

Any advice?

Superglue?

Anyone?

Superglue?

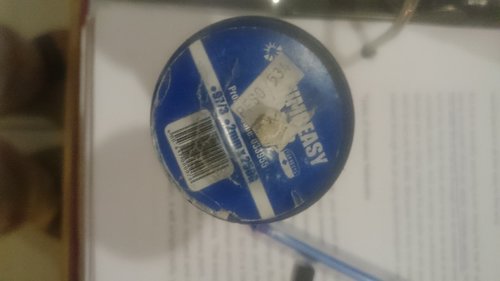

What does the switch and the solder tabs look like @RainstormZA ?

It's probably easier to reach the contacts and solder the switch while it's not mounted. Thread the wires through the hole and solder them onto the switch that way, then mount the switch afterwards. If you have enough space, you can use a crocodile clip or long-nosed pliers as a heat-sink as mentioned in the Using a Heat Sink section on this page.

Pre-tin the legs or solder tabs on the switch and also the wire you intend soldering onto the switch. Apply just enough heat to melt the solder and allow it to flow on both the tab and the wire, and then remove the iron. Let it cool down without blowing on the solder joint. Allow enough time for the first part and the switch to cool off before doing the second wire. Patience is the key.

Using a 'Helping Hands' tool may be useful in some situations..

Thanks @KuhlkatzWhat does the switch and the solder tabs look like @RainstormZA ?

It's probably easier to reach the contacts and solder the switch while it's not mounted. Thread the wires through the hole and solder them onto the switch that way, then mount the switch afterwards. If you have enough space, you can use a crocodile clip or long-nosed pliers as a heat-sink as mentioned in the Using a Heat Sink section on this page.

Pre-tin the legs or solder tabs on the switch and also the wire you intend soldering onto the switch. Apply just enough heat to melt the solder and allow it to flow on both the tab and the wire, and then remove the iron. Let it cool down without blowing on the solder joint. Allow enough time for the first part and the switch to cool off before doing the second wire. Patience is the key.

Using a 'Helping Hands' tool may be useful in some situations..

Problem with this switch is it doesn't work on both sides of the button. I have to use the bottom part in the middle and that's when it breaks. Even a slight bit of heat and it just comes apart.

Image above is the same as what I'm using.

@RainstormZA maybe if you solder a female spade connector to your wires then push on to switch. Can't judge the size from your pic though.

Thanks @Kuhlkatz

Problem with this switch is it doesn't work on both sides of the button. I have to use the bottom part in the middle and that's when it breaks. Even a slight bit of heat and it just comes apart.

View attachment 158146

Image above is the same as what I'm using.

Mmm, it looks more like these are intended for a spring-loaded contact style fit as opposed to soldering.

I'd try 'engaging' the swich to the 'on' position so it makes contact and allow the innards to act as part of the heat sink, and clamp a Crocodile clip from either side to 'pin' down and retain the centre contact for tinning first.

If the solder does not take that easily on the contact surface, you can try to finely scratch it with a sharp object and then do the tinning and soldering.

If that does not work, you can always try to source something similar to this Wire Glue.

Thank you, that's more like what I need to do.

Mmm, it looks more like these are intended for a spring-loaded contact style fit as opposed to soldering.

I'd try 'engaging' the swich to the 'on' position so it makes contact and allow the innards to act as part of the heat sink, and clamp a Crocodile clip from either side to 'pin' down and retain the centre contact for tinning first.

If the solder does not take that easily on the contact surface, you can try to finely scratch it with a sharp object and then do the tinning and soldering.

If that does not work, you can always try to source something similar to this Wire Glue.

Basically I used flux as if it's a glue to get the solder to stick first. Like you said, patience so it needs to cool first then add solder-flux on wire and drop on top of it.

@Bulldog it's actually the size of your thumbnail.

what wattage soldering iron are you using and what solder wire are u using ??

No idea, cheap soldering iron and I can't remember the name of the wire - bought it long ago, the roll lasts you ages. Guy asked me what I'm soldering - said electronics and he gave me that one specifically for electrical/electronics wiring.what wattage soldering iron are you using and what solder wire are u using ??

30 watts is enough power. post a pick of the tip of the soldering iron.

Also I think u are taking too long to solder and hence the heat transfer, practice soldering two pieces of wire or some other electronics, target is to solder within two seconds of touching the soldering iron.

Unlike what many people think, soldering is a fine skill and takes practice. I love this video, it teaches soldering starting from basics

Last edited:

I have a question for you, @Faiyaz Cheulkar - can you use any damp sponge to clean the tip?

depends on the material of the sponge. I use a small peice of old cotton rag to clean the tip when it's hot.I have a question for you, @Faiyaz Cheulkar - can you use any damp sponge to clean the tip?

Last edited:

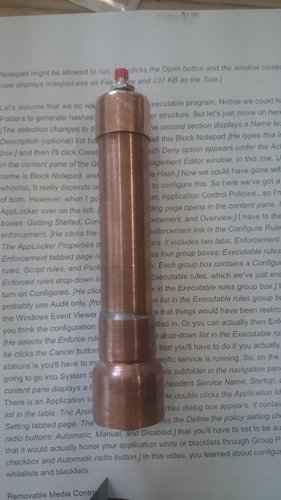

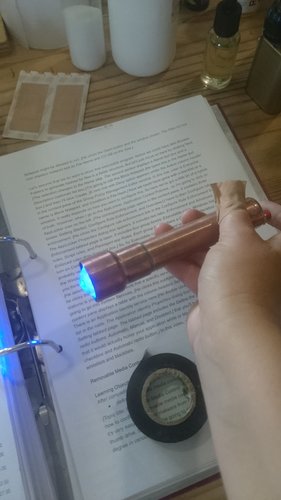

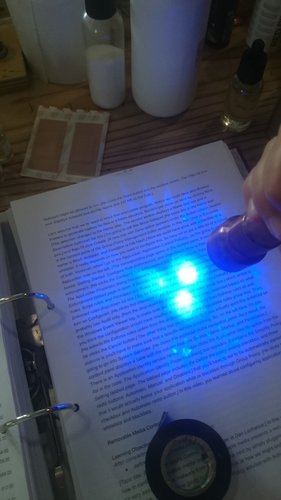

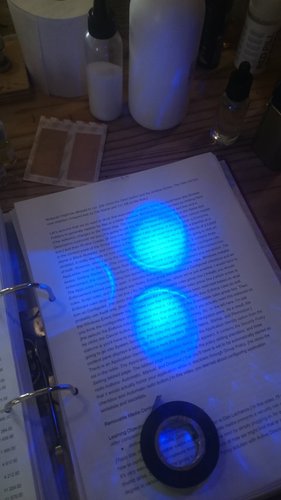

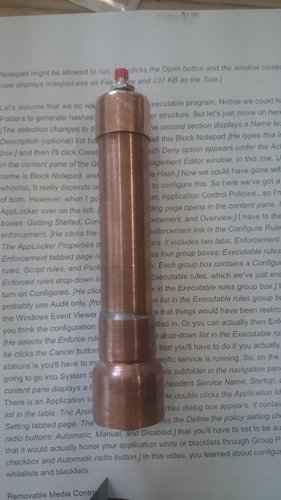

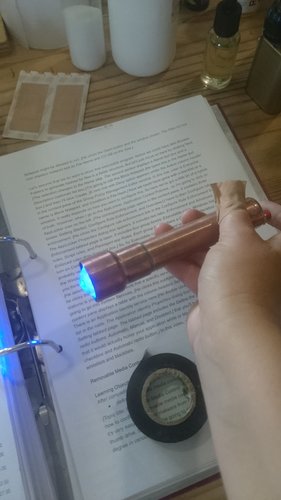

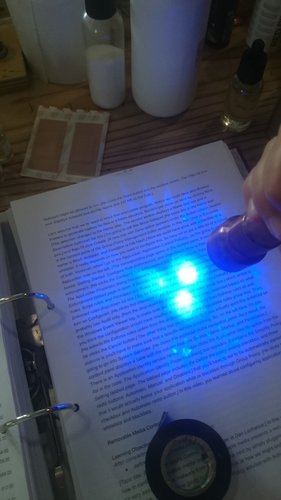

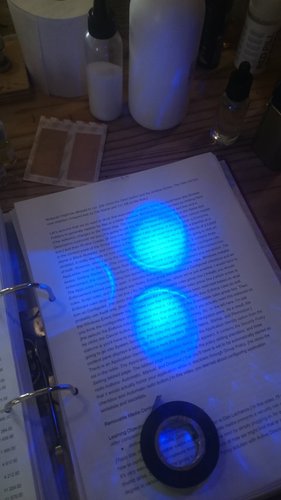

Torch completed

Ps. @Faiyaz Cheulkar, my tip had to be swapped out for a spare, no wonder I was having issues with soldering. How often do they need to be replaced?

Ps. @Faiyaz Cheulkar, my tip had to be swapped out for a spare, no wonder I was having issues with soldering. How often do they need to be replaced?

Never replaced mine, I only stand paper it before I use it or some times file it a little to take off the oxide layer.Torch completed

View attachment 158253 View attachment 158254 View attachment 158255 View attachment 158256 View attachment 158257 View attachment 158258

Ps. @Faiyaz Cheulkar, my tip had to be swapped out for a spare, no wonder I was having issues with soldering. How often do they need to be replaced?

Sent from my SM-A730F using Tapatalk

Here we go - recycled PSU box, switch and fan fitted with a TP4056 charger and 18650 battery.

I know it's been a while since I posted in here.

I just wanted to say Red Pill is flipping good in the Gear RTA @Rob Fisher. The flavour in that RTA is really good, I believe that the low power requirement is suited for Red Pill and the Gear RTA does it justice. I've just finished two tanks already.

Things have been hectic of late. Still waiting to hear if my UK visa is approved. Did a massive "spring-cleaning" and working on building up my juice bottles en mass in case I get approved to go to the UK as the first two months I will need to find my feet, with a new job offer waiting for me there and a lot of research into everything to do with the UK.

I think I'm ready to go.

I just wanted to say Red Pill is flipping good in the Gear RTA @Rob Fisher. The flavour in that RTA is really good, I believe that the low power requirement is suited for Red Pill and the Gear RTA does it justice. I've just finished two tanks already.

Things have been hectic of late. Still waiting to hear if my UK visa is approved. Did a massive "spring-cleaning" and working on building up my juice bottles en mass in case I get approved to go to the UK as the first two months I will need to find my feet, with a new job offer waiting for me there and a lot of research into everything to do with the UK.

I think I'm ready to go.

I know it's been a while since I posted in here.

I just wanted to say Red Pill is flipping good in the Gear RTA @Rob Fisher. The flavour in that RTA is really good, I believe that the low power requirement is suited for Red Pill and the Gear RTA does it justice. I've just finished two tanks already.

Things have been hectic of late. Still waiting to hear if my UK visa is approved. Did a massive "spring-cleaning" and working on building up my juice bottles en mass in case I get approved to go to the UK as the first two months I will need to find my feet, with a new job offer waiting for me there and a lot of research into everything to do with the UK.

I think I'm ready to go.

Winner Winner Chicken Dinner @RainstormZA!

I spent two years in England after school. Did Factory work and lived in the Spalding/Boston area. Had the time of my life. Living on minimum wage over there seemed to be a lot easier than on a decent salary here. I am sure you will have a great time.

Yeah any job is better than nothing. I'm actually willing to go outside my scope just to support myself. Most of the IT jobs are not flexible for a deaf person. So back to square one with word of mouth through people I know as this job offer is through my stepdad's sister's daughter who I will be working with.I spent two years in England after school. Did Factory work and lived in the Spalding/Boston area. Had the time of my life. Living on minimum wage over there seemed to be a lot easier than on a decent salary here. I am sure you will have a great time.

It's temporary so I will need to find something before the 4 months are over.

Similar threads

- Replies

- 26

- Views

- 1K