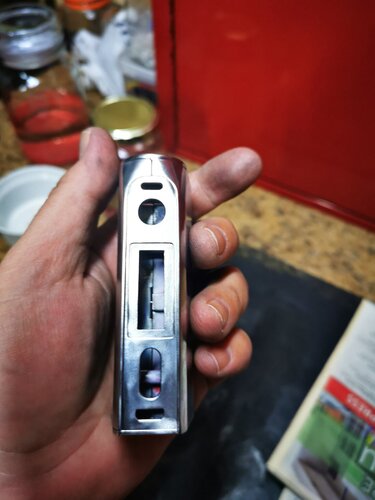

You just need the oven to be hot enough and loose heat gradually over time.

When you open the door you loose heat so basically the oven stays hot after insertion of said parts.

50⁰ is what you need and baking it at 180⁰ won't do any good.

Like I said you need the oven hot. Same as baking a cake. The oven needs to be hot before you place the cake batter inside otherwise the cake would flop.

Same with the parts your curing in the oven. Even heat distribution so you don't get hard and soft surface on the same part.

You also don't have to bake it. But then you'd have to give it enough coats to counter ear and tear.

It's a good thing I'm not into baking cakes with the way I understand instructions

Maybe ill just heat up the oven to 70 degrees it can go and wait for the thermostat to switch off. Then add the parts leave for 10 minutes and then cut the power. It's the best my brain can do right now, lol. I had nightmares about vape gear all night after breaking that 510 and really didn't get much rest and was up at the crack of dawn again this morning.