Good evening my fellow village people.

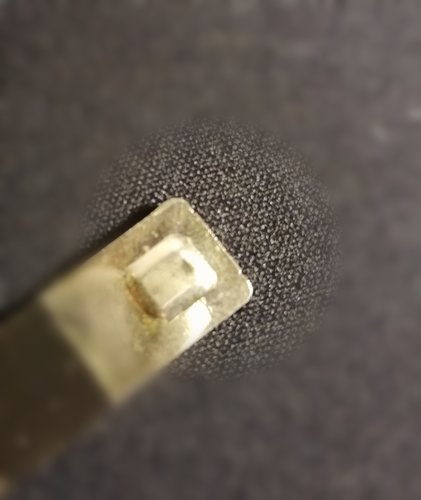

I have loomed through the mech forum and the search tab for anything relating to arch marks when it comes to mechanical tubes.

I'm sure some poeple on this forum has experienced battery arching some time in their mechanical use.

I have looked on youtube and on some other pages but everyone says something different on this topic. Apparently all mechs arch no matter which one it is and the lower you build the harder the arch wil be because of the higher draw from the cell.

Questions:

1) How to clean the marks from your batteries?

2) The cause, can it be fixed?

3) The dangers of having arch marks on your battery?

4) Does a multi point fire pin create more arching than one solid pin?

Current setup: VGOD Pro mech2 with 0.13 / vtc5a

Thank you in advance. Any advice is welcome.

I have loomed through the mech forum and the search tab for anything relating to arch marks when it comes to mechanical tubes.

I'm sure some poeple on this forum has experienced battery arching some time in their mechanical use.

I have looked on youtube and on some other pages but everyone says something different on this topic. Apparently all mechs arch no matter which one it is and the lower you build the harder the arch wil be because of the higher draw from the cell.

Questions:

1) How to clean the marks from your batteries?

2) The cause, can it be fixed?

3) The dangers of having arch marks on your battery?

4) Does a multi point fire pin create more arching than one solid pin?

Current setup: VGOD Pro mech2 with 0.13 / vtc5a

Thank you in advance. Any advice is welcome.