Turns out CNC's are similar to mods, you always seem to need 1 more.

While waiting for my laser module to arrive, which finally made it today, I decided to build a new and better machine.

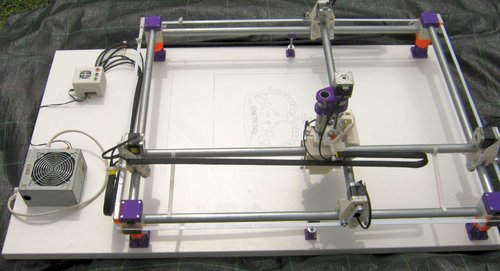

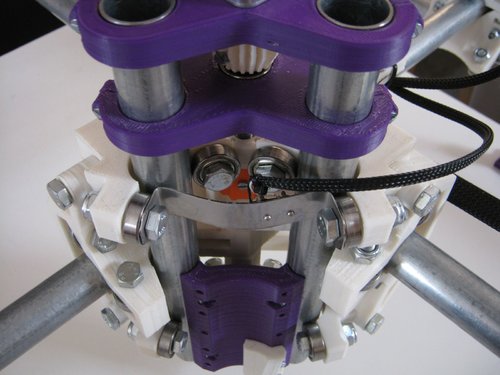

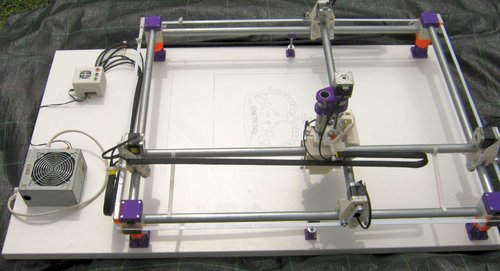

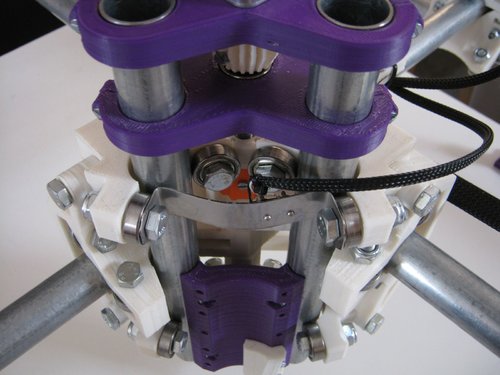

The MPCNC is mostly printed plastic using standard 608ZZ bearings on metal EMT conduit.

Downloaded the parts from Thingiverse and started with the 92 hr print, time for my 3D printer to earn its keep.

Parts came to R2700, not including 5 Minebea 17PM J 437 steppers scrounged out of a Xerox Workcenter and kindly donated to my diy cause.

The ATX psu out of an old pc and the uno and cnc shield from my previous build.

The whole shebang took about 2 weeks to assemble and went together fairly easily.

ATX psu, arduino uno and cnc shield, 500mm X 700mm x 70mm (Z height) working area.

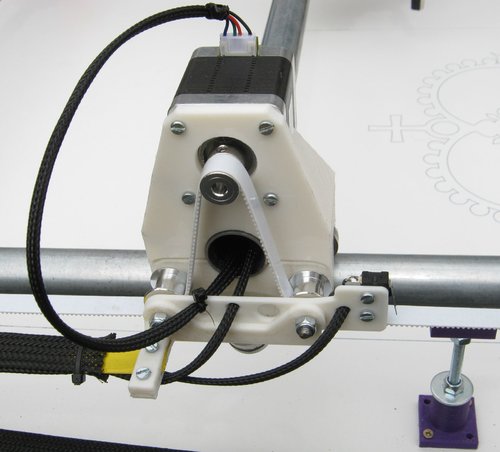

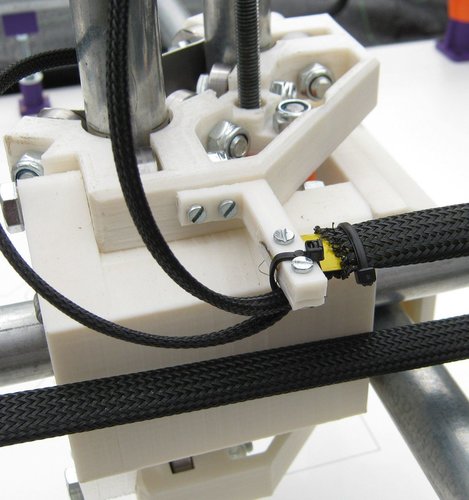

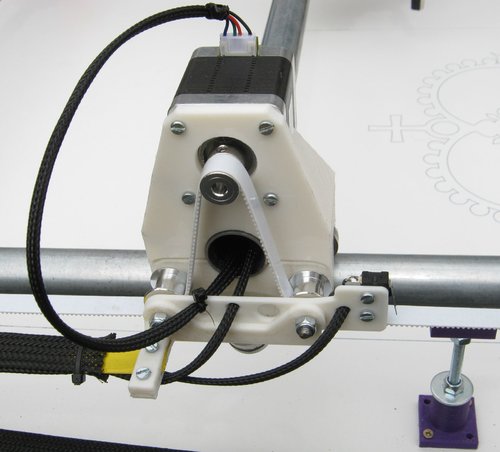

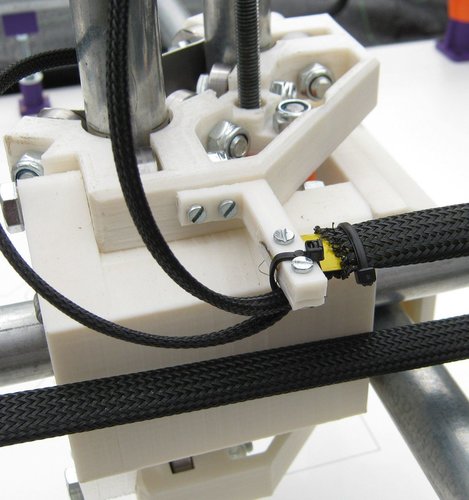

The designer mentioned a novel way of cable management using a tape measure, my implementation of the idea, works similarly to a cable chain.

The tape measure brackets were cobbled up in Tinkercad.

Z max endstop for my peace of mind when homing, not really needed, but I feel happier.

One of my 1st "to do's" was a Banksy spray paint stencil, drawn on the cnc and cut out by hand and graffiti'd on my wall.

Girl and balloon, needs some outline touchup as there is a lot of over spray on a stipple plaster wall.

Im very happy with the machine which seems quite capable and would recommend it as a starting point for anyone interested in cnc'ing.

Most folk mount a Dewalt DW660 or 611 so its up to the task of milling too.

While waiting for my laser module to arrive, which finally made it today, I decided to build a new and better machine.

The MPCNC is mostly printed plastic using standard 608ZZ bearings on metal EMT conduit.

Downloaded the parts from Thingiverse and started with the 92 hr print, time for my 3D printer to earn its keep.

Parts came to R2700, not including 5 Minebea 17PM J 437 steppers scrounged out of a Xerox Workcenter and kindly donated to my diy cause.

The ATX psu out of an old pc and the uno and cnc shield from my previous build.

The whole shebang took about 2 weeks to assemble and went together fairly easily.

ATX psu, arduino uno and cnc shield, 500mm X 700mm x 70mm (Z height) working area.

The designer mentioned a novel way of cable management using a tape measure, my implementation of the idea, works similarly to a cable chain.

The tape measure brackets were cobbled up in Tinkercad.

Z max endstop for my peace of mind when homing, not really needed, but I feel happier.

One of my 1st "to do's" was a Banksy spray paint stencil, drawn on the cnc and cut out by hand and graffiti'd on my wall.

Girl and balloon, needs some outline touchup as there is a lot of over spray on a stipple plaster wall.

Im very happy with the machine which seems quite capable and would recommend it as a starting point for anyone interested in cnc'ing.

Most folk mount a Dewalt DW660 or 611 so its up to the task of milling too.