Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

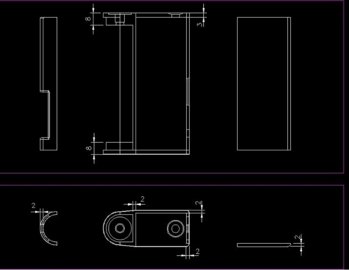

Hosh Tokolosh/rhino V1 For Review.

- Thread starter TylerD

- Start date

- Status

- Not open for further replies.

Thank you. As you see, some additional info now supplied in this thread. Looking forward to that opinion.Take it where it comes from, I will definitely get a true professional opinion this weekend.

I have a raw tumbled Reo and it has no "ugly oxidation spots and scratches"?Tumble is laymen's term for bead or sand blasting to give it a mat finish, it does not contribute to the hardness or protection of the natural / raw Alumina. The only way to protect is either powder coating, spray painting or anodizing.

Jip, that's how I felt @johanct , but I am not a metallurgic engineer. So any input will be appreciated.@TylerD , 2mm thickness on such short spans are quite strong. I don't see the need to increase it at all. What is imperative is to anodize the Alumina on production runs. Maybe someone with more experience on Alumina structural properties can provide more/better comments.

I will also ask the mechanical engineers at my work.

Whatever we decide, the Rhino must feel and be as solid as anything. Imo that is not negotiable.

Will we only anodize in natural color or other colors?

Will a colored anodizing hold, or scratch etc?

A lot of options when we anodize in colors...

View attachment 2438

Colour anodizing is exactly the same as natural anodizing, and as the natural doesn't come off, so will the colour not come off.

Awesome!Colour anodizing is exactly the same as natural anodizing, and as the natural doesn't come off, so will the colour not come off.

Would a powder coated mod not handle drops and scratches better?

Both methods do have pro's and cons - If you really want to make it durable spray painting stuff like Plasti Dip is the answer, but it won't give it the same "expensive" good looking feel than anodizing. To see more about Plasti Dip: http://www.plastidipsa.co.za/

Amazing conversations here - way out of my field.

But so happy there are people with knowledge in this space.

I agree, this thing has to be durable and tough - like a Rhino

But so happy there are people with knowledge in this space.

I agree, this thing has to be durable and tough - like a Rhino

Looking good. How will the half round front part and side cover attach to the main body? Apologies if this was already discussed and I missed it ..

The side will slide in like the REo and the front part will be held with small magnets like the Reo top.Looking good. How will the half round front part and side cover attach to the main body? Apologies if this was already discussed and I missed it ..

The question of powder coating came up , i have had plenty experience with powder coating and aluminuim , my dad worked for hullets /ali industries for 25+ years , we were one of the many test families for power coated pots and pans and all sorts of other things , my dad still has his running boards on his isuzu pickup that were powder coated blue . if you really want a hard wearing coating you should look at powder coating and for colours the range is endless .

Ok , so where do one source them?Especially if Nd2Fe14B also called Neodynium, magnets are used - amazing magnetic material. I think that's the type, considering the size to power ratio @denizenx illustrated above.

You can also check with hobby shops, rare earth magnets are extremely popular with table top wargamers.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 243

- Replies

- 15

- Views

- 1K

- Replies

- 0

- Views

- 360