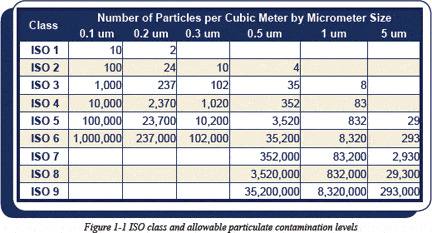

Any of the local juice manufacturers care to provide proof of ISO certification for their manufacturing environment?

Or at least proof that the process is completed in a lab environment. Or bathtub, whatever the case may be?

TX.

Or at least proof that the process is completed in a lab environment. Or bathtub, whatever the case may be?

TX.