Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Emergency fix

- Thread starter Resistance

- Start date

How’s it holding up @Resistance ?

Good MacGuyver move!

Good MacGuyver move!

HI @Silver. She's still going strong, but arching is an issue I have to polish the contacts about twice a day.How’s it holding up @Resistance ?

Good MacGuyver move!

I've just cleaned out the pod on the Drag and I got this brass shim sheet I want to try next

But I think copper would do better.

I'll test the brass first with the hopes it does good enough

There's a quick and dirty method of getting rid of the arc ... The conditions required to initiate an arc depend on the voltage across the opening switch contacts, and the current at the time of opening. If you place a capacitor across the switch contacts, the capacitor acts like a short circuit when the contacts open and the capacitor charges, reducing the current flow through the switch to zero. The capacitor charges at the rate of using the formula t = RC, where R can be calculated from R = V/I, V being the voltage across the switch contacts and I being the current flowing at the time of the break, although there is an easier way / rule of thumb that says use 1uF per Amp of current flowing through the switch.

So if we assume that that's an MTL tank at say 1 Ohm, and your battery voltage is 3.7 Volts, then I = 3.7Amps, and a capacitor of 3.7uF rated at at least double the voltage is all that is required ... The closest value to that would be a 4.7uF capacitor at 52cents from Mantech. https://www.mantech.co.za/ProductInfo.aspx?Item=65M4920-H

So if we assume that that's an MTL tank at say 1 Ohm, and your battery voltage is 3.7 Volts, then I = 3.7Amps, and a capacitor of 3.7uF rated at at least double the voltage is all that is required ... The closest value to that would be a 4.7uF capacitor at 52cents from Mantech. https://www.mantech.co.za/ProductInfo.aspx?Item=65M4920-H

Brilliant thought.There's a quick and dirty method of getting rid of the arc ... The conditions required to initiate an arc depend on the voltage across the opening switch contacts, and the current at the time of opening. If you place a capacitor across the switch contacts, the capacitor acts like a short circuit when the contacts open and the capacitor charges, reducing the current flow through the switch to zero. The capacitor charges at the rate of using the formula t = RC, where R can be calculated from R = V/I, V being the voltage across the switch contacts and I being the current flowing at the time of the break, although there is an easier way / rule of thumb that says use 1uF per Amp of current flowing through the switch.

So if we assume that that's an MTL tank at say 1 Ohm, and your battery voltage is 3.7 Volts, then I = 3.7Amps, and a capacitor of 3.7uF rated at at least double the voltage is all that is required ... The closest value to that would be a 4.7uF capacitor at 52cents from Mantech. https://www.mantech.co.za/ProductInfo.aspx?Item=65M4920-H

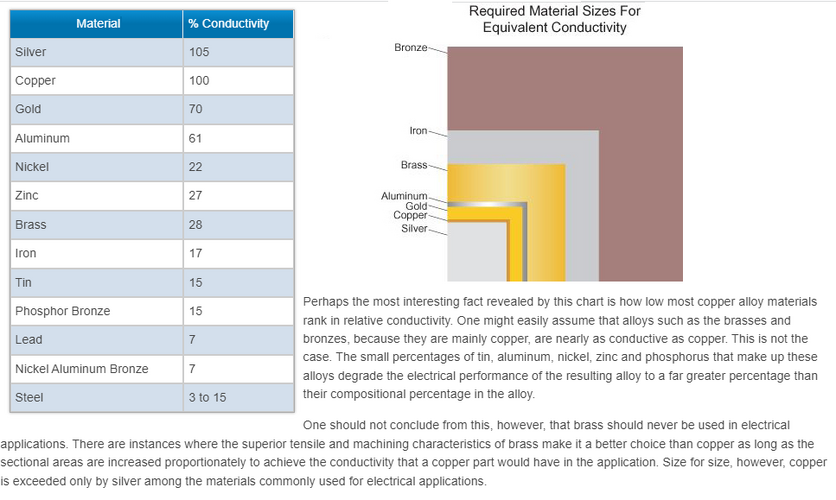

And what do you think about replacing the aluminum with brass? Because Im sure copper is the better conductor between the three.

I've changed to the brass strip. Vaping is more consistent unlike the aluminum , but the brass strip is a bit on the thin side and light pressure makes it work. (unsafe if not in the hand)

I need to double it or something.

Sure I'll think of a way to make it better. Then a proper cleaning as because in thinking of a touch up job aswell.

I need to double it or something.

Sure I'll think of a way to make it better. Then a proper cleaning as because in thinking of a touch up job aswell.

Attachments

Sounds good! ... All things equal ... Phosphor Bronze would be your best bet, as it has better tensile strength, (translated to "spring" in this context). This would be followed by bronze, followed by brass, followed by annealed copper followed by copper, followed by aluminium, (although I would suggest something like Duralium vs. Aluminium if you were to go for lower mass and retain tensile stress and conductivity).I've changed to the brass strip. Vaping is more consistent unlike the aluminum , but the brass strip is a bit on the thin side and light pressure makes it work. (unsafe if not in the hand)

I need to double it or something.

Sure I'll think of a way to make it better. Then a proper cleaning as because in thinking of a touch up job aswell.

Last edited:

Well noted. The only issue I have is the tensile strength. Other than that it still performs well. Great for that matter with regards to what the table above explains. Then again this brass sheet is used as an electrical shim material so I don't know the exact composition, but it was made for electrical applications.Sounds good! ... All things equal ... Phosphor Bronze would be your best bet, as it has better tensile strength, (translated to "spring" in this context). This would be followed by bronze, followed by brass, followed by annealed copper followed by copper, followed by aluminium, (although I would suggest something like Duralium vs. Aluminium if you were to go for lower mass and retain tensile stress and conductivity).

View attachment 275871

Great to see @Resistance !!

Similar threads

- Replies

- 2

- Views

- 4K

- Replies

- 0

- Views

- 384

- Replies

- 3

- Views

- 492

- Replies

- 2

- Views

- 1K