Hello, I'm having an issue lately.

I've had my mech mod as long as I can remember. In fact, over the years I've had many of them. I've only got one left now which I use mainly as a priming device for my billet box. Never had an issue with it.

I recently made a trade with a friend. I got an old MTL RTA

All was well for a few weeks. But now I'm having the mech autofire on me around 1-3 times a day. And I cant understand why. Let's set the stage:

Basic hybrid mech tube.

25R battery. Perfectly wrapped.

MTL tank drawing ~5amps.

510 pin protrudes plenty.

My button is not assembled incorrectly.

I've checked that the cause is not due to the coil shorting on the inside of the tank.

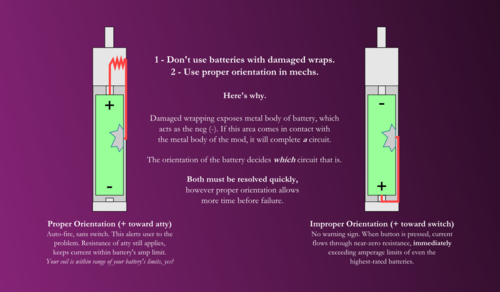

I always put my battery in the correct way so that it completes the circuit rather than dead shorting when something like this happens.

What else could it be? It's not really a major issue in that it's highly unlikely it will explode. It's way below the CDR of the battery. (+-15-25% of CDR) depending on battery level. I never leave the battery in the mech or leave it unattended.

But it's really annoying because usually by the time I've got the battery out. My cotton is cooked.

Anyone got any suggestions?

I've had my mech mod as long as I can remember. In fact, over the years I've had many of them. I've only got one left now which I use mainly as a priming device for my billet box. Never had an issue with it.

I recently made a trade with a friend. I got an old MTL RTA

All was well for a few weeks. But now I'm having the mech autofire on me around 1-3 times a day. And I cant understand why. Let's set the stage:

Basic hybrid mech tube.

25R battery. Perfectly wrapped.

MTL tank drawing ~5amps.

510 pin protrudes plenty.

My button is not assembled incorrectly.

I've checked that the cause is not due to the coil shorting on the inside of the tank.

I always put my battery in the correct way so that it completes the circuit rather than dead shorting when something like this happens.

What else could it be? It's not really a major issue in that it's highly unlikely it will explode. It's way below the CDR of the battery. (+-15-25% of CDR) depending on battery level. I never leave the battery in the mech or leave it unattended.

But it's really annoying because usually by the time I've got the battery out. My cotton is cooked.

Anyone got any suggestions?