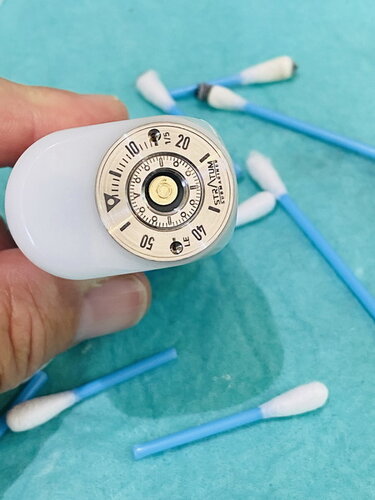

Next time you change your battery check the positive point and you may realise it needs some love and attention. A neat tip I worked out is to cut an earbud in half and use a titanium toothpick to extend the reach.

This is what it looked like before and after! I still need to do some more polishing but will do that a bit later.

This is what it looked like before and after! I still need to do some more polishing but will do that a bit later.