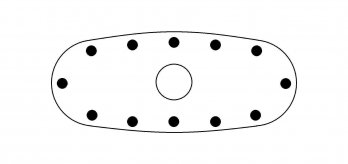

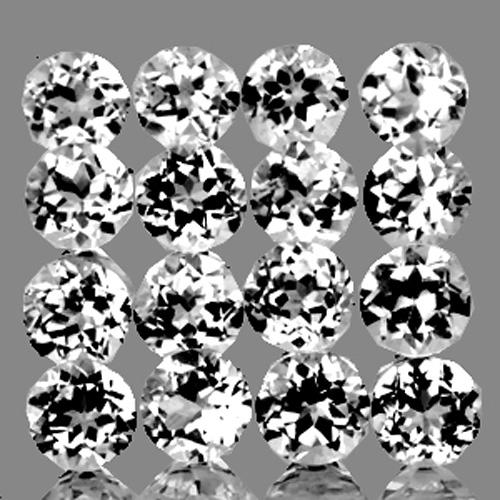

I have some Swarovski crystals, although they have some sort of coating on the back, so I spose they're closer to "embellishments" than crystals, Id like to set them into drilled pockets on a brushed aluminium plate and was wondering what a decent method would be.

Hot melt glue's out of the question and so is CA glue, it might damage the backing and there's always that white smoke from curing, 2 part epoxy maybe? any other ideas?

They are 3mm in dia and 2mm in height.

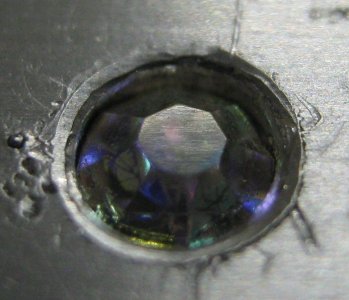

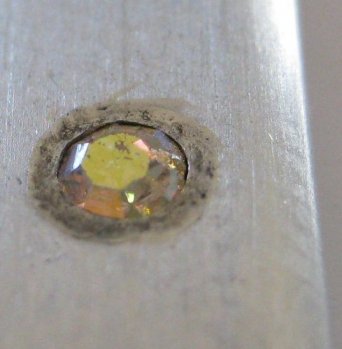

Heres a pic of experiments on a scrap piece trying to find the right drill depth.

Hot melt glue's out of the question and so is CA glue, it might damage the backing and there's always that white smoke from curing, 2 part epoxy maybe? any other ideas?

They are 3mm in dia and 2mm in height.

Heres a pic of experiments on a scrap piece trying to find the right drill depth.