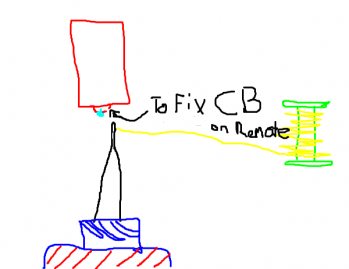

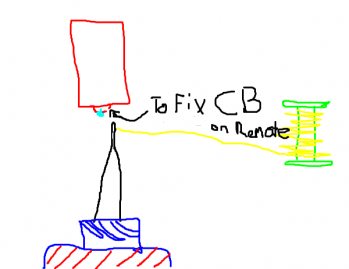

Okay this may sound crazy, BUT if I don't ask I will go crazy by lunch time. I have a Istick 60w, Vortice dripper and about 10m of kanthal 24AWG and about 2m 28AWG. My question is.... Can I make a soldering iron out of this? What I was thinking was to use a 5cm piece of 24 kanthal folded in half, with a very narrow loop right in the middle to solder with.  In the picture is my Istick with the vortice deck and the wire from the two post holes to form the loop. In yellow is the solder wire that "should then flow over the loop in the direction of what ever Circuit Board connection I am trying to fix. Theoretically I can then solder in VW mode so as not to damage the CB I am working on.

In the picture is my Istick with the vortice deck and the wire from the two post holes to form the loop. In yellow is the solder wire that "should then flow over the loop in the direction of what ever Circuit Board connection I am trying to fix. Theoretically I can then solder in VW mode so as not to damage the CB I am working on.

My question is----- Will this work? I have a samsung 25R5 battery 20Amp the resistance of the loop and length of wire is aprox 0.3 Ohm with a diameter of the loopy part at 4mm. Steam engine says my Amp draw will be 15amps at 60w and 8amps at 20w, so this is safe. Will it be effective?

Is it safe? obviously I wont heat the wire constantly but rather pulse it according to my needs and the melting point of the solder wire. Any suggestions? Any advise? Any Judgement?, all is welcome.

Important side note - I am not an electrical genius, but I understand the laws of physics pretty well, math not a problem either. I do like to experiment with new ideas and will do tons of research before I Build/Invent something potentially dangerous.

In the picture is my Istick with the vortice deck and the wire from the two post holes to form the loop. In yellow is the solder wire that "should then flow over the loop in the direction of what ever Circuit Board connection I am trying to fix. Theoretically I can then solder in VW mode so as not to damage the CB I am working on.

In the picture is my Istick with the vortice deck and the wire from the two post holes to form the loop. In yellow is the solder wire that "should then flow over the loop in the direction of what ever Circuit Board connection I am trying to fix. Theoretically I can then solder in VW mode so as not to damage the CB I am working on.My question is----- Will this work? I have a samsung 25R5 battery 20Amp the resistance of the loop and length of wire is aprox 0.3 Ohm with a diameter of the loopy part at 4mm. Steam engine says my Amp draw will be 15amps at 60w and 8amps at 20w, so this is safe. Will it be effective?

Is it safe? obviously I wont heat the wire constantly but rather pulse it according to my needs and the melting point of the solder wire. Any suggestions? Any advise? Any Judgement?, all is welcome.

Important side note - I am not an electrical genius, but I understand the laws of physics pretty well, math not a problem either. I do like to experiment with new ideas and will do tons of research before I Build/Invent something potentially dangerous.