Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nickel Builds

- Thread starter Yiannaki

- Start date

lol, I think that build is pretty much its size limit, but it all went to hell when I tried rewicking it, Nickel is just too soft. I now have a 24g Kanthal (2.5mm) build in the Bellus and have come to the conclusion that I don't like Nickel or 24g Kanthal. 26g Kanthal is still my weapon of choice.I cant fit anything bigger than duel 2.5mm into my bellus.

I want to just give you a hug, for getting a 3mm ID into that little bugger!!!!!!

I must say that my Rx200 works better in T.C. than any of my other mods except my DNA 200s escribe capability.I'm with you there, the eVic VT with the Ego Mega was a disaster but the DNA200 is a completely different animal, I think I'm going to enjoy it once I understand it all better

@Ezekiel nice work,I'm tired of ni200 both for health and lack of ease I want to start using SS and would like to hear members thoughts on it compared to nic. and Ti.Hi Daniel

Nichrome (Nichrome80) and Nickel (Ni200) are two entirely different materials, with the only common element is that they both contain metallic nickel. But in every other respect they are different.

How different? A lot. In terms of TC, the one is TC-usable (Ni200) and the other not. Specifically, Nichrome doesn't have a measurable (in terms of what a mod can detect) change in resistance when the temperature changes. Here is a graph (from www.steam-engine.org) which shows the change in temperature with the change in resistance:

View attachment 41056

Quite flat, right? In comparison, here is the same chart for Ni200:

View attachment 41057

So in other words, if you try to run TC for Nichrome, your mod (if you have a decent, updated one) will probably bomb you back to power/Kanthal/wattage mode, or give an error. If you don't have the newest of mods, it will probably think you are running actual Nickel, and it will assume the temperature doesn't change at all from room temperature, so it will just continue firing until you see some glorious fire from your driptip.

In terms of resistativity, they are worlds apart as well. Ni200 have a very low base resistance:

View attachment 41058

(This is 8 wraps, 2mm ID, single coil). You can see the resistance is 0.056 Ohm - suuuper low. The resistivity is 0.75 Ohm per meter.

On the other hand, Nichrome looks like this:

View attachment 41059

Same build (8 wraps @ 2.0 mm ID) gives 0.641 Ohm, with a resistivity of 8.46 Ohm/meter. Muuuch higher than Ni200. In fact, Nichrome is very much in the range as Kanthal:

View attachment 41060

TL;DR. Nichrome (or NiChrome80) cannot be used for TC, but is a nice, light-weight and easy-to-work and tastier alternative to Kanthal. Nickel (or Ni200) can be used only for TC - it generally builds too low for power builds, gets hot super quick if not temp controlled and oxidizes when it does so.

Hope it helps! If you really want to use Nichrome for TC, you can twist a strand of Nichrome with a strand of Ni200, like some crazy fools are doing.I personally use Titatium (and recently Stainless Steel with DNA200) for TC builds - prefer it over Nickel for both health reasons (my own) and the fact that Ni is so damn squishy I mess more coils up than what I actually can vape.

I have never managed to get a satisfactory TC vape from SS until the DNA200. The resistance changes are just too small, in the range of most mod's accuracy window. In addition, because of the low TCR, any differences in the alloy from manufacturor to manufacturor changes the actual temp-resistance relationship tremendously... so even if you got the stock TFR profike from steam engine or your mod has a stock/linear curve pre-installed, it tends to work sub-par for each different wire and each different coil. Im away from my PC, but Ive got a nice graph to show what I mean.@Ezekiel nice work,I'm tired of ni200 both for health and lack of ease I want to start using SS and would like to hear members thoughts on it compared to nic. and Ti.

On the DNA200, Ive messed around eith the steam engine curve until I had a decent temp-resistance relationship... and then I built in a 'buffer' region - a region where the temp remains the same despite any resistance changes. The idea was that the device should not change output voltage for a small range of resistance changes, instead of a static single resistance limit. It worked great for SS... but, as Ive said, its the only time Ive managed to nail SS TC.

That said, I might have had a really bad SS wire in the first place... who knows. Was UD, so should ne good quality...

SS still gives a very nice non-TC vape, and is super easy to work with... its just a tweaky as hell wire to get TC correct with. Maybe if you twist it with Ni?

Btw,I tried a parallel Ti/Kanthal build today... what a fail. Ti is so super annoying to work with...

Sent from my GT-I9195 using Tapatalk

Thanks, sounds like a lot of work and you obviously are more expert than most,but I may give it a try. Totally agree about Ti have had nothing but trouble and the build I got to work tasted not so great.When will they develop T.C.for Kanthal?I have never managed to get a satisfactory TC vape from SS until the DNA200. The resistance changes are just too small, in the range of most mod's accuracy window. In addition, because of the low TCR, any differences in the alloy from manufacturor to manufacturor changes the actual temp-resistance relationship tremendously... so even if you got the stock TFR profike from steam engine or your mod has a stock/linear curve pre-installed, it tends to work sub-par for each different wire and each different coil. Im away from my PC, but Ive got a nice graph to show what I mean.

On the DNA200, Ive messed around eith the steam engine curve until I had a decent temp-resistance relationship... and then I built in a 'buffer' region - a region where the temp remains the same despite any resistance changes. The idea was that the device should not change output voltage for a small range of resistance changes, instead of a static single resistance limit. It worked great for SS... but, as Ive said, its the only time Ive managed to nail SS TC.

That said, I might have had a really bad SS wire in the first place... who knows. Was UD, so should ne good quality...

SS still gives a very nice non-TC vape, and is super easy to work with... its just a tweaky as hell wire to get TC correct with. Maybe if you twist it with Ni?

Btw,I tried a parallel Ti/Kanthal build today... what a fail. Ti is so super annoying to work with...

Sent from my GT-I9195 using Tapatalk

lol, I think that build is pretty much its size limit, but it all went to hell when I tried rewicking it, Nickel is just too soft. I now have a 24g Kanthal (2.5mm) build in the Bellus and have come to the conclusion that I don't like Nickel or 24g Kanthal. 26g Kanthal is still my weapon of choice.

There is a hardened nickel which behaves more like kanthal for building and re-wicking. Spaced coils work way better in my experience. I actually only every built around 20 kanthal coils. I moved from commercial to kanthal then nickel within weeks. Its been around 8 months now of nickel exclusively. Mind you dual nickel is something I've never gotten correct.

Most likely, never.When will they develop T.C.for Kanthal?

Or at least not a very accurate version of it.

Kanthal has a very flat TCR curve.

What that means is that the resistance of kanthal doesnt change ENOUGH with applied temperature in the regions that mods can detect on a millisecond/resistance basis.

SS also has a very tight TCR curve, but kanthal is right up there with Nichrome when it comes to non-TC usability.

@Ezekiel ,If twisted w/ Ni would you use the Ni or SS setting?I have never managed to get a satisfactory TC vape from SS until the DNA200. The resistance changes are just too small, in the range of most mod's accuracy window. In addition, because of the low TCR, any differences in the alloy from manufacturor to manufacturor changes the actual temp-resistance relationship tremendously... so even if you got the stock TFR profike from steam engine or your mod has a stock/linear curve pre-installed, it tends to work sub-par for each different wire and each different coil. Im away from my PC, but Ive got a nice graph to show what I mean.

On the DNA200, Ive messed around eith the steam engine curve until I had a decent temp-resistance relationship... and then I built in a 'buffer' region - a region where the temp remains the same despite any resistance changes. The idea was that the device should not change output voltage for a small range of resistance changes, instead of a static single resistance limit. It worked great for SS... but, as Ive said, its the only time Ive managed to nail SS TC.

That said, I might have had a really bad SS wire in the first place... who knows. Was UD, so should ne good quality...

SS still gives a very nice non-TC vape, and is super easy to work with... its just a tweaky as hell wire to get TC correct with. Maybe if you twist it with Ni?

Btw,I tried a parallel Ti/Kanthal build today... what a fail. Ti is so super annoying to work with...

Sent from my GT-I9195 using Tapatalk

It depends. If you have a DNA200, you can get the slightly altered TCR curve from the wire wizard on Steam-engine, and although it won't be 100% correct, it will be a good enough starting point for you to start messing around with it until you've found your vape. Here, I've used the parallel setting in Steam-engine (as it doesn't allow you to use twisted option with two different wire types... go figure. The equation remains the same AFAIK):

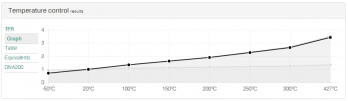

You can see the bottom faded line is the TCR curve for SS, whereas the top-most one is for Ni200. The black line is the resultant TCR (estimated) curve.

For non-DNA200 devices, it is a little bit more trickier, but you can get more or less the same result, I would venture. If you cannot change the TCR coefficient, then stick with the Ni setting - as you can see from the above graph, the changes in resistance from the Ni wire is much higher than the SS wire. Consequently, your mod will pick up these changes and determine the temperature. The small changes resulting from the SS wire will result in a few degrees inaccuracy, at most - so it might fail a cotton dry-burn test at a few degrees below the burn-point of cotton, but for most vaping related applications should be fine.

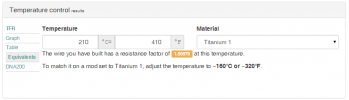

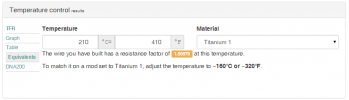

In fact, for other twisted/parallel/clapton coils of different wire types, you can estimate the temperature your mod will read in Ni-mode and the actual temperature of the coil by clicking on the Equivalents tab. For Ni/SS, it is supposedly exactly the same:

So 210 C for the Ni/SS wire in Ni mode will be equivalent to actual 210 for the wire type. But for a Ti/SS build, in Ti mode:

you have to set your mod on 160 C in order to get an actual 210. Note that these adjustments are more or less estimates.

Finally, if your mod can manually set the TCR coefficient, you can calculate the graph in Wire Wizard, copy the data from the "Table" results, paste it in Excel and calculate the TCR coefficient yourself (it is the slope of the graph...). Enter this value in your mod and should be more or less ok in vaping range, unless you have a seriously weird combination.

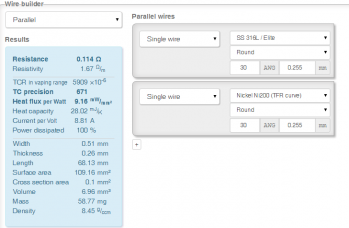

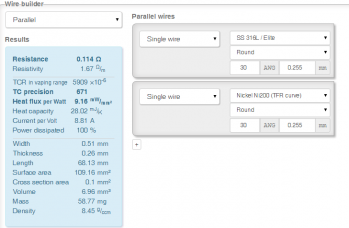

EDIT: You don't need to do it in Excel. Hell, you don't even have to google "How to calculate slope in Excel" if you had mathematics more than a few decades ago. You can just get the value in Steam-Engine, on the left hand side:

at the field saying, "TCR in vaping range". Here it is 5909E06... or 0.005909.

TL;DR: Use the wire with the higher TCR (in other words, Ni in a twisted Ni/SS build) if you cannot change any of your values on your mod manually; use the calculated TCR value if you can enter that in your mod, or download the .csv file if you have a DNA200.

You can see the bottom faded line is the TCR curve for SS, whereas the top-most one is for Ni200. The black line is the resultant TCR (estimated) curve.

For non-DNA200 devices, it is a little bit more trickier, but you can get more or less the same result, I would venture. If you cannot change the TCR coefficient, then stick with the Ni setting - as you can see from the above graph, the changes in resistance from the Ni wire is much higher than the SS wire. Consequently, your mod will pick up these changes and determine the temperature. The small changes resulting from the SS wire will result in a few degrees inaccuracy, at most - so it might fail a cotton dry-burn test at a few degrees below the burn-point of cotton, but for most vaping related applications should be fine.

In fact, for other twisted/parallel/clapton coils of different wire types, you can estimate the temperature your mod will read in Ni-mode and the actual temperature of the coil by clicking on the Equivalents tab. For Ni/SS, it is supposedly exactly the same:

So 210 C for the Ni/SS wire in Ni mode will be equivalent to actual 210 for the wire type. But for a Ti/SS build, in Ti mode:

you have to set your mod on 160 C in order to get an actual 210. Note that these adjustments are more or less estimates.

Finally, if your mod can manually set the TCR coefficient, you can calculate the graph in Wire Wizard, copy the data from the "Table" results, paste it in Excel and calculate the TCR coefficient yourself (it is the slope of the graph...). Enter this value in your mod and should be more or less ok in vaping range, unless you have a seriously weird combination.

EDIT: You don't need to do it in Excel. Hell, you don't even have to google "How to calculate slope in Excel" if you had mathematics more than a few decades ago. You can just get the value in Steam-Engine, on the left hand side:

at the field saying, "TCR in vaping range". Here it is 5909E06... or 0.005909.

TL;DR: Use the wire with the higher TCR (in other words, Ni in a twisted Ni/SS build) if you cannot change any of your values on your mod manually; use the calculated TCR value if you can enter that in your mod, or download the .csv file if you have a DNA200.

@Ezekiel ,Thanks for a great instruction.It depends. If you have a DNA200, you can get the slightly altered TCR curve from the wire wizard on Steam-engine, and although it won't be 100% correct, it will be a good enough starting point for you to start messing around with it until you've found your vape. Here, I've used the parallel setting in Steam-engine (as it doesn't allow you to use twisted option with two different wire types... go figure. The equation remains the same AFAIK):

View attachment 41305

You can see the bottom faded line is the TCR curve for SS, whereas the top-most one is for Ni200. The black line is the resultant TCR (estimated) curve.

For non-DNA200 devices, it is a little bit more trickier, but you can get more or less the same result, I would venture. If you cannot change the TCR coefficient, then stick with the Ni setting - as you can see from the above graph, the changes in resistance from the Ni wire is much higher than the SS wire. Consequently, your mod will pick up these changes and determine the temperature. The small changes resulting from the SS wire will result in a few degrees inaccuracy, at most - so it might fail a cotton dry-burn test at a few degrees below the burn-point of cotton, but for most vaping related applications should be fine.

In fact, for other twisted/parallel/clapton coils of different wire types, you can estimate the temperature your mod will read in Ni-mode and the actual temperature of the coil by clicking on the Equivalents tab. For Ni/SS, it is supposedly exactly the same:

View attachment 41306

So 210 C for the Ni/SS wire in Ni mode will be equivalent to actual 210 for the wire type. But for a Ti/SS build, in Ti mode:

View attachment 41307

you have to set your mod on 160 C in order to get an actual 210. Note that these adjustments are more or less estimates.

Finally, if your mod can manually set the TCR coefficient, you can calculate the graph in Wire Wizard, copy the data from the "Table" results, paste it in Excel and calculate the TCR coefficient yourself (it is the slope of the graph...). Enter this value in your mod and should be more or less ok in vaping range, unless you have a seriously weird combination.

EDIT: You don't need to do it in Excel. Hell, you don't even have to google "How to calculate slope in Excel" if you had mathematics more than a few decades ago. You can just get the value in Steam-Engine, on the left hand side:

View attachment 41308

at the field saying, "TCR in vaping range". Here it is 5909E06... or 0.005909.

TL;DR: Use the wire with the higher TCR (in other words, Ni in a twisted Ni/SS build) if you cannot change any of your values on your mod manually; use the calculated TCR value if you can enter that in your mod, or download the .csv file if you have a DNA200.

Haha, thanks @Silver! I think you are totally confusing any knowledge I have with just pure emphusiasm!Dr @Ezekiel - you certainly have a superb way of explaining your wonderful knowledge on these advanced devices!

I must admit, all the adjustability is making me quite tempted

It all started with the DNA200 in order to learn... but Ive realized it is not necessary, you can get almost all the same functionality on other devices as well. Specifically the RX200 I would think! That said, if you have the money (and more importantly, the time and the tinkering curiosity!) for a DNA200 it really pays off.

I really am trying to make some time in order to write a guide for fine-tweaking TC in eScribe... just so bloody busy this time of year!

Sent from my GT-I9195 using Tapatalk

Hi, I thought I may as well give my  . I ordered 24AWG Kanthal from one of our vendors, opened the parcel and a 10m roll of Ni200 24AWG was sitting there, all allone like it was destined to be, I mean who uses 24AWG Ni200? so I phoned them and I got my Kanthal. Now what to do with the Ni200? Even at 11 wraps I cannot get the resistance high enough to read on my Istick 60w, so what now? I read up on combining Kanthal and Ni200 in temp mode, so I took twisted 28 Kanthal and paralel wrapped it around two legs of these BIG paperclips that I soldered together, so kind of an oval coil at 9wraps it is 1.5cm long, installed on my Vortice and it measures in at 0.06ohm. 31w and 190deg, it gives real good flavour just not enough of a cloud for me to be satisfied, anyway, the Kanthal is technichally just there to space the coil and make it look cool. Sadly I cannot post a pic, lighting is bad, here is a sketch.

. I ordered 24AWG Kanthal from one of our vendors, opened the parcel and a 10m roll of Ni200 24AWG was sitting there, all allone like it was destined to be, I mean who uses 24AWG Ni200? so I phoned them and I got my Kanthal. Now what to do with the Ni200? Even at 11 wraps I cannot get the resistance high enough to read on my Istick 60w, so what now? I read up on combining Kanthal and Ni200 in temp mode, so I took twisted 28 Kanthal and paralel wrapped it around two legs of these BIG paperclips that I soldered together, so kind of an oval coil at 9wraps it is 1.5cm long, installed on my Vortice and it measures in at 0.06ohm. 31w and 190deg, it gives real good flavour just not enough of a cloud for me to be satisfied, anyway, the Kanthal is technichally just there to space the coil and make it look cool. Sadly I cannot post a pic, lighting is bad, here is a sketch.

. I ordered 24AWG Kanthal from one of our vendors, opened the parcel and a 10m roll of Ni200 24AWG was sitting there, all allone like it was destined to be, I mean who uses 24AWG Ni200? so I phoned them and I got my Kanthal. Now what to do with the Ni200? Even at 11 wraps I cannot get the resistance high enough to read on my Istick 60w, so what now? I read up on combining Kanthal and Ni200 in temp mode, so I took twisted 28 Kanthal and paralel wrapped it around two legs of these BIG paperclips that I soldered together, so kind of an oval coil at 9wraps it is 1.5cm long, installed on my Vortice and it measures in at 0.06ohm. 31w and 190deg, it gives real good flavour just not enough of a cloud for me to be satisfied, anyway, the Kanthal is technichally just there to space the coil and make it look cool. Sadly I cannot post a pic, lighting is bad, here is a sketch.

. I ordered 24AWG Kanthal from one of our vendors, opened the parcel and a 10m roll of Ni200 24AWG was sitting there, all allone like it was destined to be, I mean who uses 24AWG Ni200? so I phoned them and I got my Kanthal. Now what to do with the Ni200? Even at 11 wraps I cannot get the resistance high enough to read on my Istick 60w, so what now? I read up on combining Kanthal and Ni200 in temp mode, so I took twisted 28 Kanthal and paralel wrapped it around two legs of these BIG paperclips that I soldered together, so kind of an oval coil at 9wraps it is 1.5cm long, installed on my Vortice and it measures in at 0.06ohm. 31w and 190deg, it gives real good flavour just not enough of a cloud for me to be satisfied, anyway, the Kanthal is technichally just there to space the coil and make it look cool. Sadly I cannot post a pic, lighting is bad, here is a sketch.Attachments

Similar threads

- Replies

- 1

- Views

- 1K

- Replies

- 0

- Views

- 1K

- Replies

- 0

- Views

- 1K