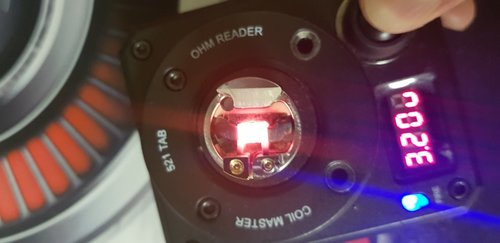

Doing some testing with SS mesh as a wick because I'm looking for something that's more convenient than rewicking every 8ml.

Some say SS mesh gives superb flavour but I have not seen this catch on here in the many years it's been available.

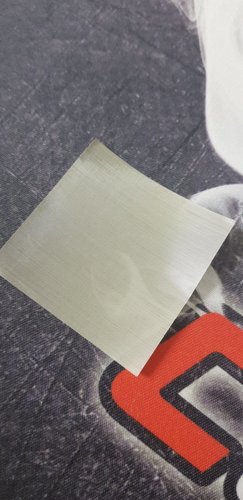

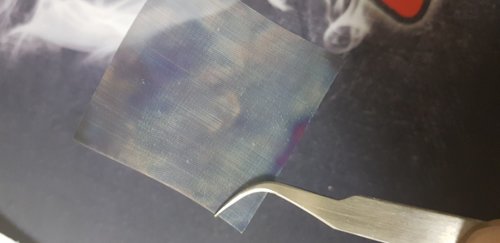

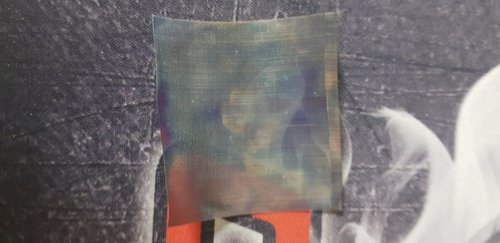

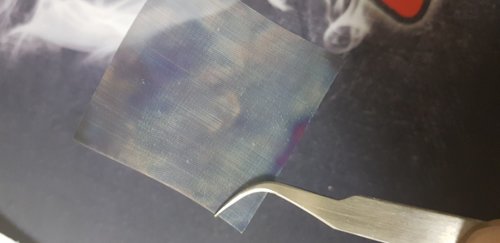

In the interest of science I have aquired some SS mesh and have started the process of rolling and quenching etc. There are many YouTube videos on how to properly prepare SS mesh so I won't be going into detail.

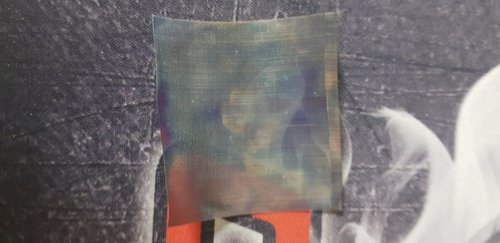

So far:

So far, the ss mesh is very absorbent and has a capillary action going for it.

Just waiting for the ultrasonic to finish before I test it in a RDA.

I have seen RTAs wicked with SS mesh but I will hold off until my rolling skills improve and if the effort preparing this is all worthwhile.

Some say SS mesh gives superb flavour but I have not seen this catch on here in the many years it's been available.

In the interest of science I have aquired some SS mesh and have started the process of rolling and quenching etc. There are many YouTube videos on how to properly prepare SS mesh so I won't be going into detail.

So far:

So far, the ss mesh is very absorbent and has a capillary action going for it.

Just waiting for the ultrasonic to finish before I test it in a RDA.

I have seen RTAs wicked with SS mesh but I will hold off until my rolling skills improve and if the effort preparing this is all worthwhile.