Since I started vaping, I have always been dubious about the tiny fragile grub screws that are on most of the rebuildable tanks I have purchased. I have read that some vapers dislike these and refuse to buy tanks with them. I am now one of these vapers. I was waiting for my day to come when one of these little pieces of excuses for screws would strip.

Before I continue, I want to emphasise that I have tempered all my grub screws in order to strengthen these. (Big Guy from Sir Vape recently made a video clip showing how to do this with a blow torch and Olive Oil) Secondly, I ALWAYS screw these grubs in gently without using too much pressure as I am mindful of how easy these are prone to stripping.

I am not knocking the Fuji GTA RTA in particular, but today I was building a single coil, 5 wrap on it. I was trying to screw in the one grub screw, but it would not absorb into the wire. It got stuck and stripped. After an hour I managed to remove it and replace it. I must say, I have always battled to get thin wire in these posts with the grubs, so I had to go with thicker wire.

Here are some pics:

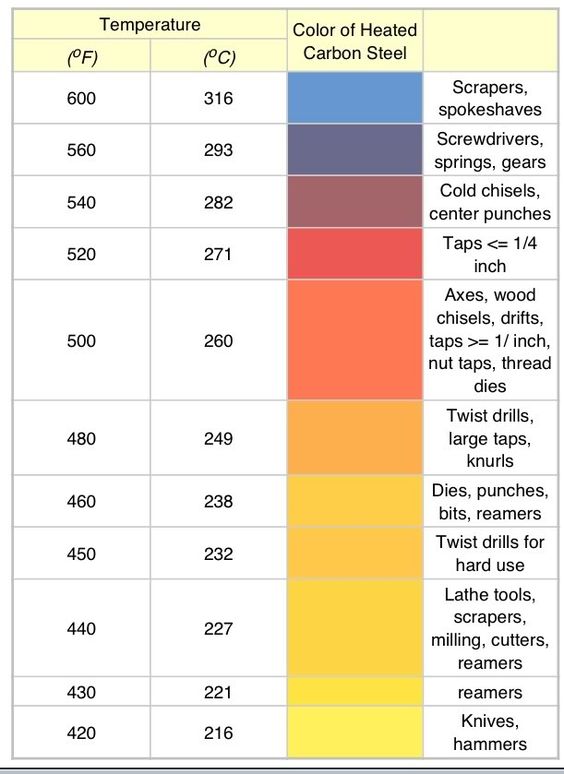

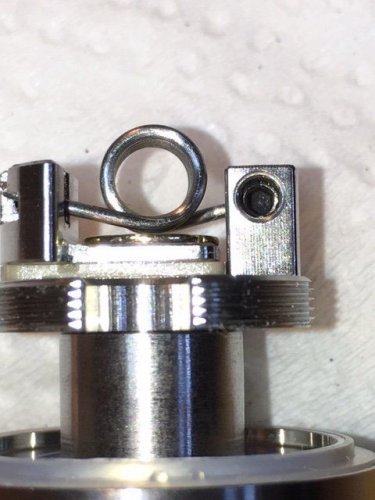

The grub screw on this single coil Fuji GTA got stuck. I was using the correct allan key.

As you can see, it is rounded and stripped, the hexagonal shape is now a circle.

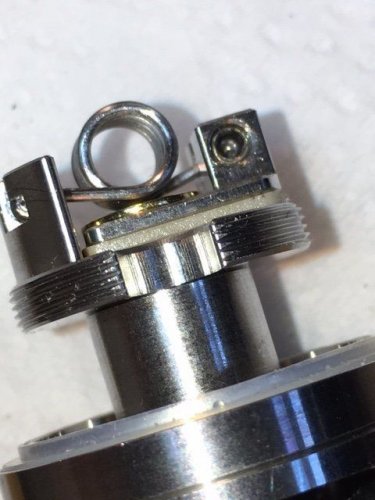

Turned around, the other grub screw is OK, retaining its hex shape.

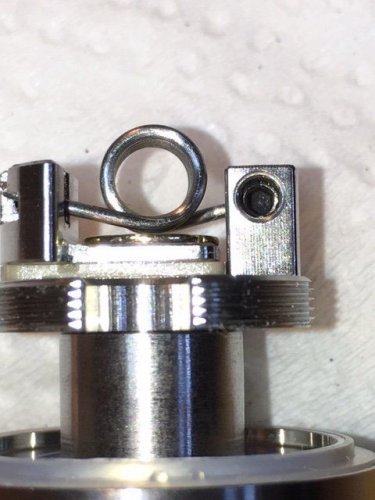

Bad quality pics, but you can see the left one, which I had to "Pull a Rabbit out of the hat" to remove is round, and the right one is OK. I removed it by forcing a bigger hex screw driver in and pushing hard until it sunk into the metal and basically formed another hole.

I opened the Fuji GTA box, took out a spare grub screw and it fitted perfectly. Yes, this is not the tool it came with, but the red screw driver tool it came with is exactly the same size!

Conclusion:

I will only buy an RDA or RTA if it has decent size Phillips or Flat head screws. I cannot imagine having to deal with this problem again and perhaps it cannot be removed resulting in me having to give it to my engineer friend to remove it out with precision equipment.

And so we vape on, and learn...

Before I continue, I want to emphasise that I have tempered all my grub screws in order to strengthen these. (Big Guy from Sir Vape recently made a video clip showing how to do this with a blow torch and Olive Oil) Secondly, I ALWAYS screw these grubs in gently without using too much pressure as I am mindful of how easy these are prone to stripping.

I am not knocking the Fuji GTA RTA in particular, but today I was building a single coil, 5 wrap on it. I was trying to screw in the one grub screw, but it would not absorb into the wire. It got stuck and stripped. After an hour I managed to remove it and replace it. I must say, I have always battled to get thin wire in these posts with the grubs, so I had to go with thicker wire.

Here are some pics:

The grub screw on this single coil Fuji GTA got stuck. I was using the correct allan key.

As you can see, it is rounded and stripped, the hexagonal shape is now a circle.

Turned around, the other grub screw is OK, retaining its hex shape.

Bad quality pics, but you can see the left one, which I had to "Pull a Rabbit out of the hat" to remove is round, and the right one is OK. I removed it by forcing a bigger hex screw driver in and pushing hard until it sunk into the metal and basically formed another hole.

I opened the Fuji GTA box, took out a spare grub screw and it fitted perfectly. Yes, this is not the tool it came with, but the red screw driver tool it came with is exactly the same size!

Conclusion:

I will only buy an RDA or RTA if it has decent size Phillips or Flat head screws. I cannot imagine having to deal with this problem again and perhaps it cannot be removed resulting in me having to give it to my engineer friend to remove it out with precision equipment.

And so we vape on, and learn...

. I also enjoy the clamp style.

. I also enjoy the clamp style.