Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Start Of Afriville And The Tokolosh/rhino Project

- Thread starter johan

- Start date

- Status

- Not open for further replies.

Remember this is the rainbow nation, so we have to make it work for everyone...

Hybrid - that can be used as an elec./mech mod..by a flick of a switch (dont even know if this is possible)

Can be bottom fed(Reo) or Tank..or both

Should be expandable to take battery of choice..(this might be pushing it a bit...)

Hybrid - that can be used as an elec./mech mod..by a flick of a switch (dont even know if this is possible)

Can be bottom fed(Reo) or Tank..or both

Should be expandable to take battery of choice..(this might be pushing it a bit...)

Now that is an idea...just print the whole bloody thing in heat resistant plastic...

oooh 3d printing

I do mostly piping, but do use different 3d packages. Plant 3d, cadworx, inventor and showcase. the 3D print will be awesome for sure. I think we must just agree on a concept. What I don't know is how the chip with the screen will be lying in the the mod, and connectors and button sizes etc etc. Think we must start getting the parts together we are going to use with their sizes. I need to draw the parts first to shuffle them around in the mod.@TylerD, what software do you use for your draughting. Once a design is agreed upon, I could help out with some 3D visualisations & renders as I specialize in Revit and other 3D software. We could even go as far as printing a 3D model if we want to.

@TylerD, I was also wondering how all the "guts" would be placed and fastened. Although fastening details is a every day thing for me (Architectural drafting), this is slightly different because we have to take into consideration heat soak, electric conductivity, watertightness of chip etc. Nevertheless, I'll have a crack at it once we know dimensions of the components.

I can help draw/model the components if needed.I need to draw the parts first to shuffle them around in the mod.

Awesome stuff. We just need to find out what parts we will be using. I am not good with electronics.I can help draw/model the components if needed.

Really liking this thread! Looks like its gonna have everything in!

If it can make coffee also then its perfection!

Sent from my BlackBerry 9800 using Tapatalk

If it can make coffee also then its perfection!

Sent from my BlackBerry 9800 using Tapatalk

Well see about the coffee. It will be able to generate it's own juice tho.Really liking this thread! Looks like its gonna have everything in!

If it can make coffee also then its perfection!

Sent from my BlackBerry 9800 using Tapatalk

If its gonna be a box mod put the screen next to the 510 connection on top! When you take a vape you can look down past the atomizer and see the screen!I do mostly piping, but do use different 3d packages. Plant 3d, cadworx, inventor and showcase. the 3D print will be awesome for sure. I think we must just agree on a concept. What I don't know is how the chip with the screen will be lying in the the mod, and connectors and button sizes etc etc. Think we must start getting the parts together we are going to use with their sizes. I need to draw the parts first to shuffle them around in the mod.

Sent from my BlackBerry 9800 using Tapatalk

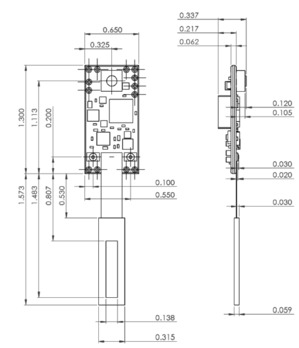

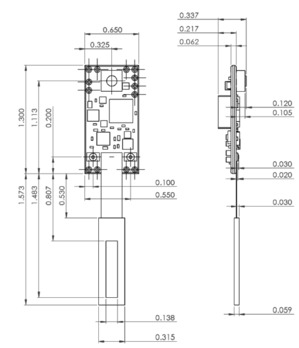

Like all your comments above; regarding switches: Non-electronic version - I suggest lockable (like something on the microstick (see pic below), Electronic version: let's stick for know with the DNA30? (3 switches required: (fire, up and down) - If we position electronics on top section, minimal wires required, hence minimal lossess and visa versa). If you need higher resolution file of dimensions pm me with your email address. To convert dimensions from inch to mm = xx inch x 25.4

MICROSTICK

DNA30 note: yellow part is flexable and can be bend 360 degrees - up down buttons can be moved, Fire button = violet colour

Dimensions (inches)

??

SWITCH POSITION IDEA

Would like to hear your comments

MICROSTICK

DNA30 note: yellow part is flexable and can be bend 360 degrees - up down buttons can be moved, Fire button = violet colour

Dimensions (inches)

??

SWITCH POSITION IDEA

Would like to hear your comments

Last edited:

inch to mm would be - inch x 25.4 = mmTo convert dimensions from inch to mm = xx inch X 0.3907

inch to mm would be - inch x 25.4 = mm

Apologies my bad, I had it inverted mm to inch = x 0.3907

Cool stuff. Where can I look for the switches that we are going to use? What kind of switches do we need for what functions? For the fire button is it just a mechanical type that can lock? For the up/down, is it small push electronic or mechanical?

Is the switch idea on the bottom of the mech?

Is the switch idea on the bottom of the mech?

Cool stuff. Where can I look for the switches that we are going to use? What kind of switches do we need for what functions? For the fire button is it just a mechanical type that can lock? For the up/down, is it small push electronic or mechanical?

Is the switch idea on the bottom of the mech?

The lockable will be a custom lathe job. The electronic switches is already on pcb and all we need to do is custom made buttons that sits on-top of the tactile switches (I'l have a look at RS Components for button ideas).

Where do we source RM2 RDA? ( knockoffs will suffice for the first couple of proto-types) or do anyone else suggests a better bottom fed RDA?

3 & 6mm drip bottles should be easily available at local pharmaceutical packaging stores

Silicone drip tubes we can get locally at Carlin Medical Extrusions

3 & 6mm drip bottles should be easily available at local pharmaceutical packaging stores

Silicone drip tubes we can get locally at Carlin Medical Extrusions

Just a suggestion - what if a switch was used for the up and down buttons that was similar to the VTR rotary dial? I am thinking more like a thumb wheel that could rotate up or down (not continuous rotation) and this thumb wheel could be near the fire button.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 459

- Replies

- 0

- Views

- 1K

- Replies

- 9

- Views

- 2K

- Replies

- 1

- Views

- 1K