Not sure what happened where I no longer have to wait weeks before anything can be done but today got an email from Thomas to say he is despatching my order again tomorrow!Urgh, good luck

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Zirconium Wire Anyone?

- Thread starter Timwis

- Start date

I'm certainly looking forward to seeing your results, as said, I think the challenges of it softening when heated may outweigh the benefits of it's resistance to oxidation, however shock treating it to restore it's hardness aka dunking glowing coils in water may well resolve the issue?Time will tell when I get to try it, been hoping to try it for a long time so naturally have spent many hours googling it and sourcing out Youtube videos and have gone through many threads from vaping forums and Reddit going back as far as 8 years and over time it's use seams to of steadily increased if anything being held back only by availability being strictly for TC unlike SS so like Titanium very few places stock it, even most Ni200 that can be found is old stock very slowly being sold off. It's particularly popular in Greece and Germany although Tungsten is also popular in Germany but the resistance of Tungsten is even lower than Ni200 so won't be trying that any time soon!

Going back to it's malleability until I try it for myself I can only go by what others have said on the many threads discussing using zirconium that I have read through and not one person mentioned it being an issue and although the videos are not English so I don't actually understand what is being said I have watched re-wicks and cleaning of zirconium coils and they keep their shape as well as any other coil even though more effort is needed brushing the wire because like other TC only wire it shouldn't be dry burned on the up side I have found when using TC the coils and wick don't get caked up like when using power modes.

Interesting factoid on the element; South Africa produces a little more than 40% of the worlds Zircon.

Yet I bet if you want a roll of Zirconium wire for vaping you would have to import it, crazy world!South Africa produces a little more than 40% of the worlds Zircon

Indeed! ... It gets worse ... We export our grade one steel, and import crap / full of impurities steel from ChinaYet I bet if you want a roll of Zirconium wire for vaping you would have to import it, crazy world!

.......*please help me pick up my jaw off the floor...Indeed! ... It gets worse ... We export our grade one steel, and import crap / full of impurities steel from China

First impressions are excellent, baring in mind I am using the 2nd thinnest Zirconium wire Zivipf sells and it does come in 24ga which is much thicker working with it was easy. Slightly springy but that actually aided in doing the spaced coil I wanted and pretty similar to Titanium. I did do a 3.0ID coil so I could test the 3mm shoelace after @Intuthu Kagesi pointed out it's malleability but it pulled through despite the friction between wire and cotton with ease, so a relief there was no problem at all.

It set-up in TC with zero issues and early days (or couple of hours to be precise) but the flavour seams a match for Titanium which in recent times has become my wire of choice. It will need an extensive period trying different atomisers and flavours to really give a verdict but on first impressions it's going to be either slightly down, slightly up or to close to call compared to Titanium!

It set-up in TC with zero issues and early days (or couple of hours to be precise) but the flavour seams a match for Titanium which in recent times has become my wire of choice. It will need an extensive period trying different atomisers and flavours to really give a verdict but on first impressions it's going to be either slightly down, slightly up or to close to call compared to Titanium!

Last edited:

Update:

Had absolutely zero issues now after 5 days, so stable in temp control it's as simple as using power mode and I am not even using the more user friendly Replay feature. It has such a clean flavour, if you vape using Kanthal or Nichrome and then switched to Titanium or Zirconium you would find out that those wires give quite a taste with most not realising I am also in the group of people who although I find SS316l a cleaner flavour than Kanthal or Nichrome I detect a slight metallic taste which depending on the juice can be annoying. Zirconium however is giving nothing in the way of taste so is just increasing the flavour quality of my juice.

Don't know what else at the moment I can report apart from the condition of my wick and coil is top notch as if the build is fresh which as my Titanium builds are still going strong doesn't surprise me, remind me again, what's a re-wick?

Had absolutely zero issues now after 5 days, so stable in temp control it's as simple as using power mode and I am not even using the more user friendly Replay feature. It has such a clean flavour, if you vape using Kanthal or Nichrome and then switched to Titanium or Zirconium you would find out that those wires give quite a taste with most not realising I am also in the group of people who although I find SS316l a cleaner flavour than Kanthal or Nichrome I detect a slight metallic taste which depending on the juice can be annoying. Zirconium however is giving nothing in the way of taste so is just increasing the flavour quality of my juice.

Don't know what else at the moment I can report apart from the condition of my wick and coil is top notch as if the build is fresh which as my Titanium builds are still going strong doesn't surprise me, remind me again, what's a re-wick?

Sounds greatUpdate:

Had absolutely zero issues now after 5 days, so stable in temp control it's as simple as using power mode and I am not even using the more user friendly Replay feature. It has such a clean flavour, if you vape using Kanthal or Nichrome and then switched to Titanium or Zirconium you would find out that those wires give quite a taste with most not realising I am also in the group of people who although I find SS316l a cleaner flavour than Kanthal or Nichrome I detect a slight metallic taste which depending on the juice can be annoying. Zirconium however is giving nothing in the way of taste so is just increasing the flavour quality of my juice.

Don't know what else at the moment I can report apart from the condition of my wick and coil is top notch as if the build is fresh which as my Titanium builds are still going strong doesn't surprise me, remind me again, what's a re-wick?

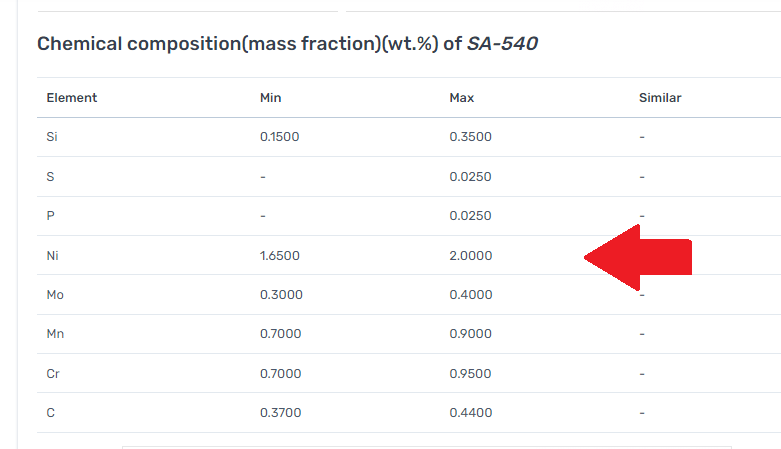

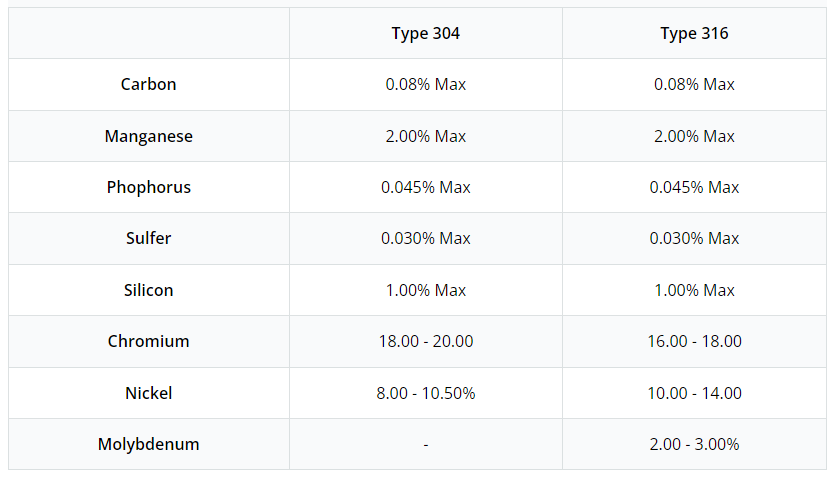

As to Stainless Steel ... there's another can of worms ... there are literally 100's of grades of it, and even the most common used in vaping 304, and 316 have a few 100 "subgrades" as can be seen below in the % range of Nickel and Chrome, to which the upper end of 316 would most certainly have a nickel "taste"

Still got the nickel free SS540 to try, I thought they all had their fair share of nickel before Wayneo sent me a sample of this, bought a spool before even trying it but then I thought nickel free, no brainer!would most certainly have a nickel "taste"

From what I am reading of course these wires are initially annealed but then both Titanium and Zirconium shouldn't be dry burned like the more commonly used wires because they are not to be heated to high temperatures. Most formal reading just says dry burning is a no no while some TC users I have spoken to say you can pulse to aid with cleaning (not like they get in the sort of state as coils using power mode) but only using a mod with TC set-up so you keep within temperature limits.I'd suggest glowing your coil and then quenching it in water to reharden it before attempting a rewick

As I said before nobody I speak to are having issues with re-wicking (it just isn't even brought up as an issue) and to be honest mate if there does turn out to be an issue like you suspect the wick and coil stays in such good nick and the cost of the wire is so cheap considering how many coils I can get out of one spool needing to do a whole new build wouldn't be the end of the world. I am eager to see how re-wicking goes but might be some wait yet.

What's SA-540? The SS430 might have a very small amount but negligible compared to the commonly used SS for vaping.

I see a typo it's SS430, that's me typing when it's getting dark because I can't be arsed to get up and switch the light on I won't edit else the following posts won't make any sense!

I have no sight of their process or product, so I I have to assume you're correct, and that you received it annealed?From what I am reading of course these wires are initially annealed but then both Titanium and Zirconium shouldn't be dry burned like the more commonly used wires because they are not to be heated to high temperatures. Most formal reading just says dry burning is a no no while some TC users I have spoken to say you can pulse to aid with cleaning (not like they get in the sort of state as coils using power mode) but only using a mod with TC set-up so you keep within temperature limits.

As I said before nobody I speak to are having issues with re-wicking (it just isn't even brought up as an issue) and to be honest mate if there does turn out to be an issue like you suspect the wick and coil stays in such good nick and the cost of the wire is so cheap considering how many coils I can get out of one spool needing to do a whole new build wouldn't be the end of the world. I am eager to see how re-wicking goes but might be some wait yet.

Annealing however is a heat treatment just like hardening and tempering , where metal is allowed to cool slowly after heating to a dull red hot. This relieves internal stresses and concurrently softens metals ... Ideally you'd want your coil hardened and or tempered, which you can do yourself by heating your coil just barely cherry red ... and then quenching it in cold water.

Have no fear, it won't form any toxic oxides, besides which, the manufacturer would have had to have heated the wire to a dull cherry red to anneal it before you received it.

Thank goodness for that clarificationI see a typo it's SS430, that's me typing when it's getting dark because I can't be arsed to get up and switch the light on I won't edit else the following posts won't make any sense!

SA-430 features the following chemical composition:

Iron = Balance out %'s of total

Carbon < 0.12%

Chromium = 16-18%

Nickel < 0.75%

Manganese < 1.0%

Silicon < 1.0%

Phosphorus < 0.040%

Sulfur < 0.30%

It just is supposed to be done under temp control not pulsing under wattage, sure you could using wattage just pulse using very low power like 6-8 watts to make sure you keep the temp under control, with thin wires used for MTL it is so very easy to bypass "Cherry Red" as the wire heats so quickly. When dry burning using wattage the coil can get much hotter than it does tamed by your juice and for example Titanium set's a light at 620 degree C (just off memory so could be slightly out but it's there bout's) it supposedly is almost impossible to put out and leaves a white powdery toxic deposit. No doubt there are some TC vapers who risk dry burning their coils as any other coils pulsing with wattage but to cover their arses they keep it to themselves rather than recommending it and when having the option of controlling the temp using TC It seems unnecessary to take risks.I have no sight of their process or product, so I I have to assume you're correct, and that you received it annealed?

Annealing however is a heat treatment just like hardening and tempering , where metal is allowed to cool slowly after heating to a dull red hot. This relieves internal stresses and concurrently softens metals ... Ideally you'd want your coil hardened and or tempered, which you can do yourself by heating your coil just barely cherry red ... and then quenching it in cold water.

Have no fear, it won't form any toxic oxides, besides which, the manufacturer would have had to have heated the wire to a dull cherry red to anneal it before you received it.

They will have very controlled heating methods, hardly a mad Tim in his lounge with a blow torchthe manufacturer would have had to have heated the wire to a dull cherry red to anneal it before you received it.

Yes mate, all wire that is sold as vaping wire (trusted source, not Cyril's Dodgy Wires) has been annealed ready for use, the old videos of vapers blow torching their wire was when most wire was bought from non vaping wire companies. A quick warm is still wise to get rid of any machine residue but as for hotspots I only ever get one if I made a complete mess of winding the coil, good quality wire should be good to go.I have to assume you're correct, and that you received it annealed

O come on ... live dangerouslyIt just is supposed to be done under temp control not pulsing under wattage, sure you could using wattage just pulse using very low power like 6-8 watts to make sure you keep the temp under control, with thin wires used for MTL it is so very easy to bypass "Cherry Red" as the wire heats so quickly. When dry burning using wattage the coil can get much hotter than it does tamed by your juice and for example Titanium set's a light at 620 degree C (just off memory so could be slightly out but it's there bout's) it supposedly is almost impossible to put out and leaves a white powdery toxic deposit. No doubt there are some TC vapers who risk dry burning their coils as any other coils pulsing with wattage but to cover their arses they keep it to themselves rather than recommending it and when having the option of controlling the temp using TC It seems unnecessary to take risks.

Actually I would have gone the other way ... A LOT of wire sold as "premium vaping wire" is grade R, as in rejected for industrial purposesYes mate, all wire that is sold as vaping wire (trusted source, not Cyril's Dodgy Wires) has been annealed ready for use, the old videos of vapers blow torching their wire was when most wire was bought from non vaping wire companies. A quick warm is still wise to get rid of any machine residue but as for hotspots I only ever get one if I made a complete mess of winding the coil, good quality wire should be good to go.

Still vaping wire is annealed which comes from Temco who supply certain brands like Wireoptim, they told me this so I asked if they knew about other suppliers and they were adamant all wire sold for vaping were annealed so could be used straight off the spool!Actually I would have gone the other way ... A LOT of wire sold as "premium vaping wire" is grade R, as in rejected for industrial purposes

I don't give a sh6t what it's melting point is if its on fire!O come on ... live dangerouslyTitanium's melting point is as close as dammit to 1724 degrees C and Zirconium at 1850 degrees C ... compared to 316 Stainless at 1375 degrees C

Similar threads

- Replies

- 1

- Views

- 2K

- Replies

- 0

- Views

- 1K

- Replies

- 2

- Views

- 2K

- Replies

- 2

- Views

- 4K