Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lekka Vape Mail

- Thread starter johan

- Start date

- Status

- Not open for further replies.

No its M7 x 0.5mm pitch taps for 510 connector threading

holy crumpets, you got taps. well done

That's awesome vape mail @johan now i need to plot to relieve you of one of those taps........??

I had to take 10 (m.o.q) - will look up the cost later and let you know

You rock dude been looking for one of those for a while now.I had to take 10 (m.o.q) - will look up the cost later and let you know

Sure you will be able to sell those easily @johan . I'l take one.I had to take 10 (m.o.q) - will look up the cost later and let you know

No its M7 x 0.5mm pitch taps for 510 connector threading

What exactly do you do with those @johan

Sent from my S4 LTE using my finger

Sounds useful, now I want one, please. BTW, great vape mail.

yup price dependant i might want/need one also

oooh just remembered, which of the three types of tap are those?

oooh just remembered, which of the three types of tap are those?

yup price dependant i might want/need one also

oooh just remembered, which of the three types of tap are those?

Apologies but I'm dumbstruct by your question, please elaborate for my poor understanding?

These are M7 x 0.5 for 510. Ego threads are M12

Sent from my GT-I9190 using Tapatalk

Sent from my GT-I9190 using Tapatalk

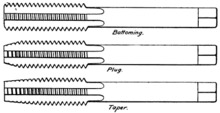

Bottoming tap or plug tap

[2] The tap illustrated in the top of the image has a continuous cutting edge with almost no taper ? between 1 and 1.5 threads of taper is typical.[3] This feature enables a bottoming tap to cut threads to the bottom of a blind hole. A bottoming tap is usually used to cut threads in a hole that has already been partially threaded using one of the more tapered types of tap; the tapered end ("tap chamfer") of a bottoming tap is too short to successfully start into an unthreaded hole. In the US, they are commonly known as bottoming taps, but in Australia and Britain they are also known as plug taps.

Intermediate tap, second tap,[2] or plug tap

[4] The tap illustrated in the middle of the image has tapered cutting edges, which assist in aligning and starting the tap into an untapped hole. The number of tapered threads typically ranges from 3 to 5.[3] Plug taps are the most commonly used type of tap.[citation needed] In the US, they are commonly known as plug taps, whereas in Australia and Britain they are commonly known as second taps.

Taper tap

The small tap illustrated at the bottom of the image is similar to an intermediate tap but has a more pronounced taper to the cutting edges. This feature gives the taper tap a very gradual cutting action that is less aggressive than that of the plug tap. The number of tapered threads typically ranges from 8 to 10.[3] A taper tap is most often used when the material to be tapped is difficult to work (e.g., alloy steel) or the tap is of a very small diameter and thus prone to breakage.

The above illustrated taps are generally referred to as hand taps, since they are, by design, intended to be manually operated. During operation, it is necessary with a hand tap to periodically reverse rotation to break the chip formed during the cutting process, thus preventing an effect called "crowding" that may cause breakage.

The most common type of power driven tap is the "spiral point" plug tap (also referred to as a "gun tap"), whose cutting edges are angularly displaced relative to the tap centerline. This feature causes the tap to continuously break the chip and eject it forward into the hole, preventing crowding. Spiral point taps are usually used in holes that go all the way through the material, so that the chips can escape. Another version of the spiral point plug tap is the spiral flute tap, whose flutes resemble those of a twist drill. Spiral flute taps are widely used in high speed, automatic tapping operations due to their ability to work well in blind holes.

Whether manual or automatic, the processing of tapping begins with forming (usually by drilling) and slightly countersinking a hole to a diameter somewhat smaller than the tap's major diameter. The correct hole diameter may be determined by consulting a drill and tap size chart, a standard reference item found in many machine shops. If the hole is to be drilled, the proper diameter is called the tap drill size.

hopefully my ignorance is just confusing the issue here

Taps come in 3 types namely starting or taper, intermediate and finishing or plug

I will look up the price and post here later, as far as I can remember it was well below the R100 mark/piece, including shipping. I'm not a reseller so not interested in profit - will sell the other 9 at what I paid for it to whoever is interested (priority to the names above that showed interest in them).

Now I have learnt something...

I was just getting used to the word "tap" when you asked what type of tap?

LOL

@johan, if I ever need to tap something, can I offer you some whiskey and we have a nice lunch in Pretoria?

Leave the whisky to the sophisticated I'm just a cheap wine drinker

- Status

- Not open for further replies.

Similar threads

- Replies

- 14

- Views

- 1K

- Replies

- 49

- Views

- 2K